Impressive Technologies

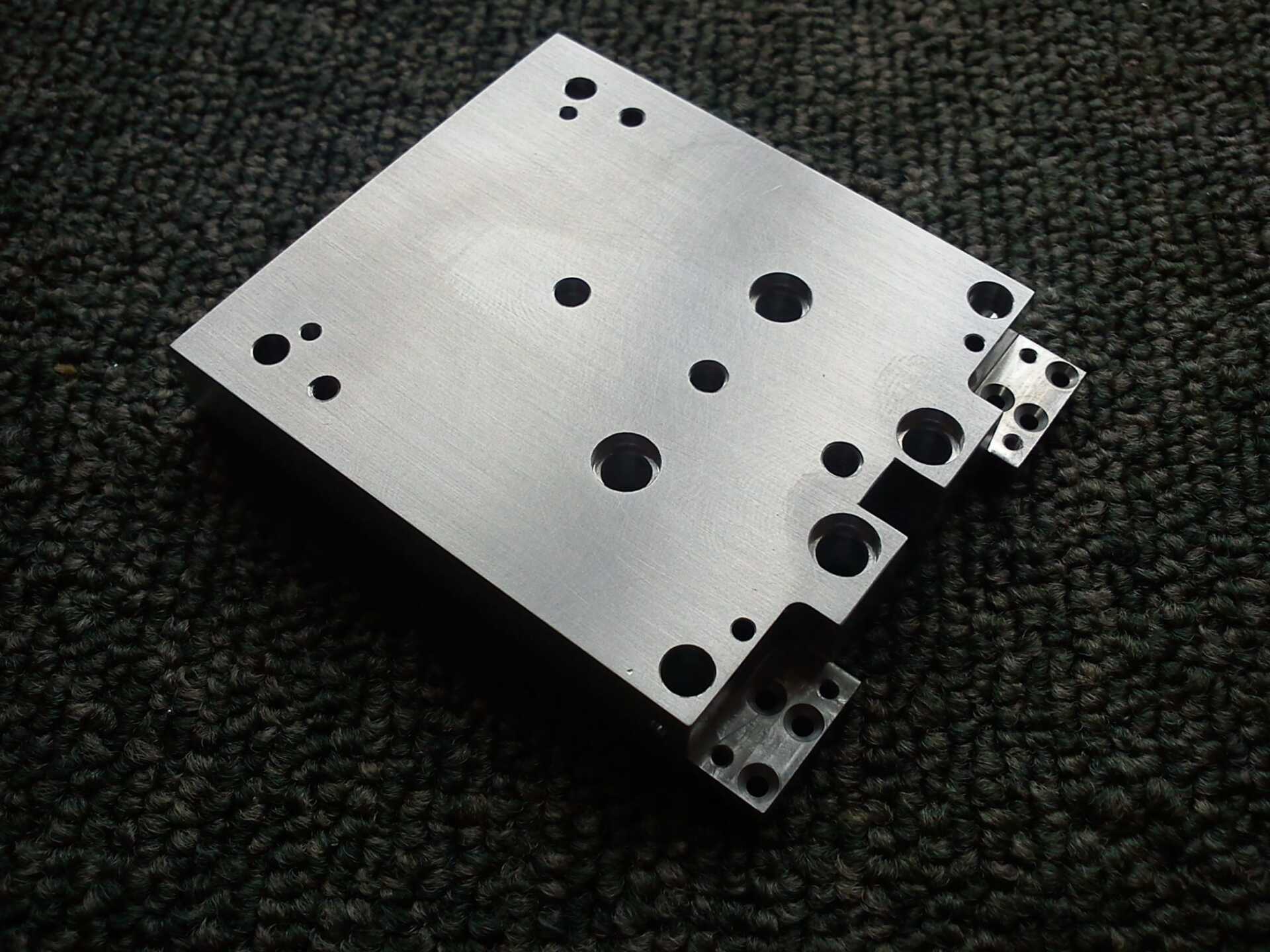

Our past engineering projects have always been completed to the highest standards thanks to our top-quality CNC machines. Our machines are efficient and versatile, allowing us to work with all manner of sizes and materials.

Quality Workmanship

We are extremely proud of our team of engineers, who are all specialists in their field. With a plethora of knowledge and experience, you can rest assured that all past and future work is in safe and professional hands.

A history of high quality engineering projects

Here at Linfield Precision Engineering Ltd, we pride ourselves on our unwavering customer satisfaction, which has been proven throughout our impressive range of past projects. Our completed work ranges from small to large engineering projects, which have all been done using quality manufacturing and an efficient service.

With 41 years of experience in the precision engineering industry, we have completed a large number of stunning projects for clients throughout the UK. If you think your project could be next, make sure to drop us an email so we can get started as soon as possible!

MILLING

- Hurco VM10 3 Axis VMC. three stackable vices 10K Spindle (2014)

- Hurco VM10 3 Axis VMC. Three stackable vices 10K Spindle (2013)

- Hurco VM1 3 Axis VMC. Three stackable vices 8K Spindle (2011)

- XYZ Opp2 VMC (2018)

- XYZ Opp2 VMC (2019)

- XYZ KRV 2000 2 Axis CNC Prototrack Turret Mill (1998)

TURNING

- XYZ Proturn RLX425 420 CNC Lathe (2020)

- XYZ Proturn RLX1630 CNC Lathe. (2020)

- Hurco TM6 Slant Bed CNC Turning (2010) Bar Feed Capacity

- HURCI TMM8 Slant Bed CNC Turning with driven tooling and C Axis (2015)

- Shun Shin Manual Lathe

- Myford manual Lathe

WELDING

- Thermal Arc 200amp Mig Welder

- Stahlwerk AC DC 200 Amp Tig Welder

- Clarke Band Saw

ANCILERIES

- Gtec programmable 250 litre screw vane compressor with air purification and dryer

- Compair 100 litre hydro-vane backup compressor

SOFTWARE

- Hurco Win-max version 9 offline suite for our Mills and Turning Centres, complete with full suite of postprocessors and DXF translators

- One CNC XR5 Post processors for all our machines

- ProD Version 8 - Solid modelling and rendering software for design and presentation

INSPECTION

- Dedicated clean room

- Insisize Vision CMM With Renishaw Probe and DXF Software.

- Micrometers, External Metrics from 25mm – 175mm, External Imperial up to 12"

- Vernier Callipers from 150mm up to 1000mm

- 1000 x 1000 Granite Surface Plate with 650mm Mitutoyo Digital Height Gauge

- All Measuring Equipment traceable and Calibrated to UKAS National Standards